Streamlining Production from Profile to Installation

Time:2025-07-04 Browse:28次

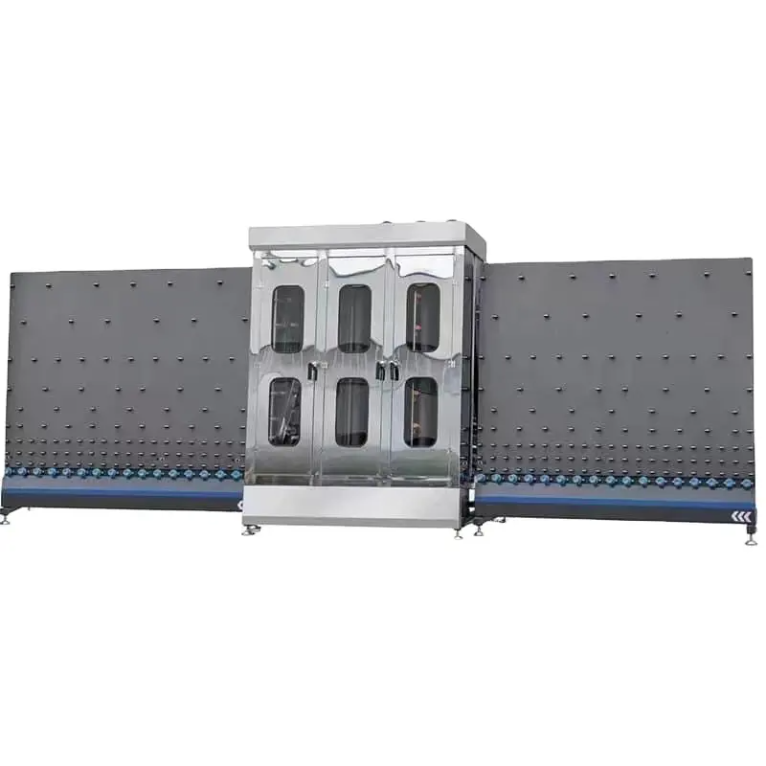

As a leading window production machine manufacturer, we design turnkey solutions that automate the entire workflow—from profile processing to hardware installation. Our modular systems adapt to both UPVC and aluminum production, ideal for manufacturers seeking flexibility.

Workflow Breakdown:

1. Profile Cutting: Double-head saws cut profiles to length with miter angles (0°-60°) using laser alignment.

2. Corner Welding/Joining: For UPVC: high-frequency welding (20-30 seconds per joint); for aluminum: robotic screwing/riveting.

3. Hardware Installation: Automatic drills place hinges, locks, and handles with millimeter precision.

4. Quality Control: Vision systems inspect seals, hardware alignment, and surface finish.

ROI Insight: A Turkish window company reduced production costs by $12/unit after implementing our integrated line, with annual output increasing from 30,000 to 75,000 units. The machine’s quick-change tooling allowed them to switch between UPVC and aluminum jobs in under 15 minutes.

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd

管理员

该内容暂无评论