B. Three pairs of rubber rollers use full solid rubber roller to ensure the cleaning effect.

C. The equipment is equipped with an acrylic protective cover to prevent water from splashing during cleaning.

D. Pure stainless steel sprinkler to ensure the durability of the equipment.

E. Special silencer cotton greatly reduces noise during operation

F. Special precision air knife to ensure uniform sealing of the seal from top to bottom.

G. The patented technology uses three air inlets to ensure that the wind speed is uniform from top to bottom and the wind is strong.

C. The equipment is equipped with an acrylic protective cover to prevent water from splashing during cleaning.

D. Pure stainless steel sprinkler to ensure the durability of the equipment.

E. Special silencer cotton greatly reduces noise during operation

F. Special precision air knife to ensure uniform sealing of the seal from top to bottom.

G. The patented technology uses three air inlets to ensure that the wind speed is uniform from top to bottom and the wind is strong.

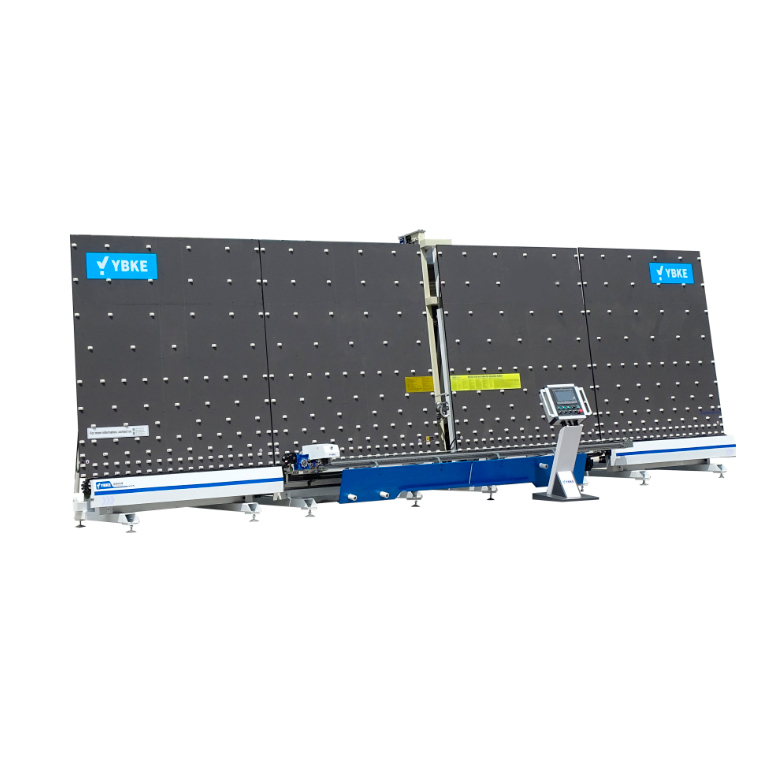

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd