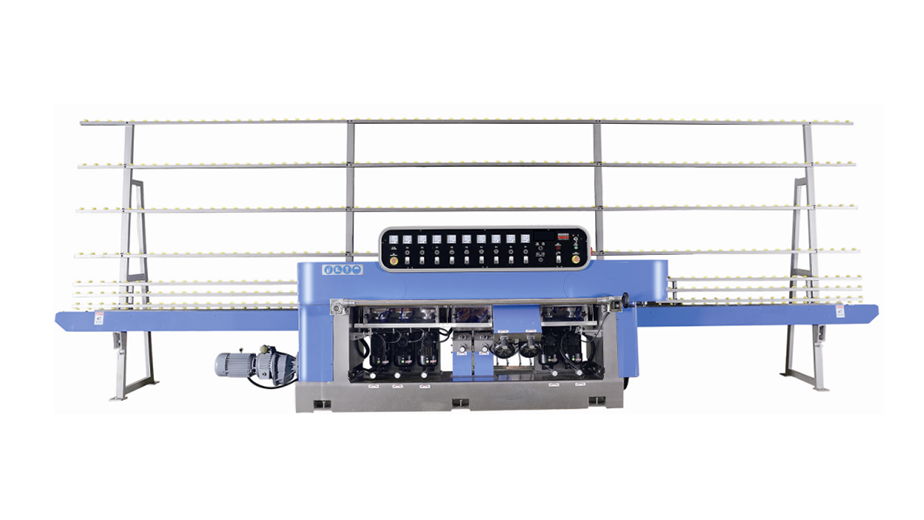

Automatic Aluminum Windows Milling Cutting Production Line

Time:2025-01-11 Browse:132次

1.The automatic feeding table can continuously and automatically clamp profiles for cutting.

2.The moving parts all adopt high-precision linear guide pairs, which run smoothly and ensure the machining accuracy.

3.The manipulator adopts imported high-precision gear rack to ensure the feeding accuracy.

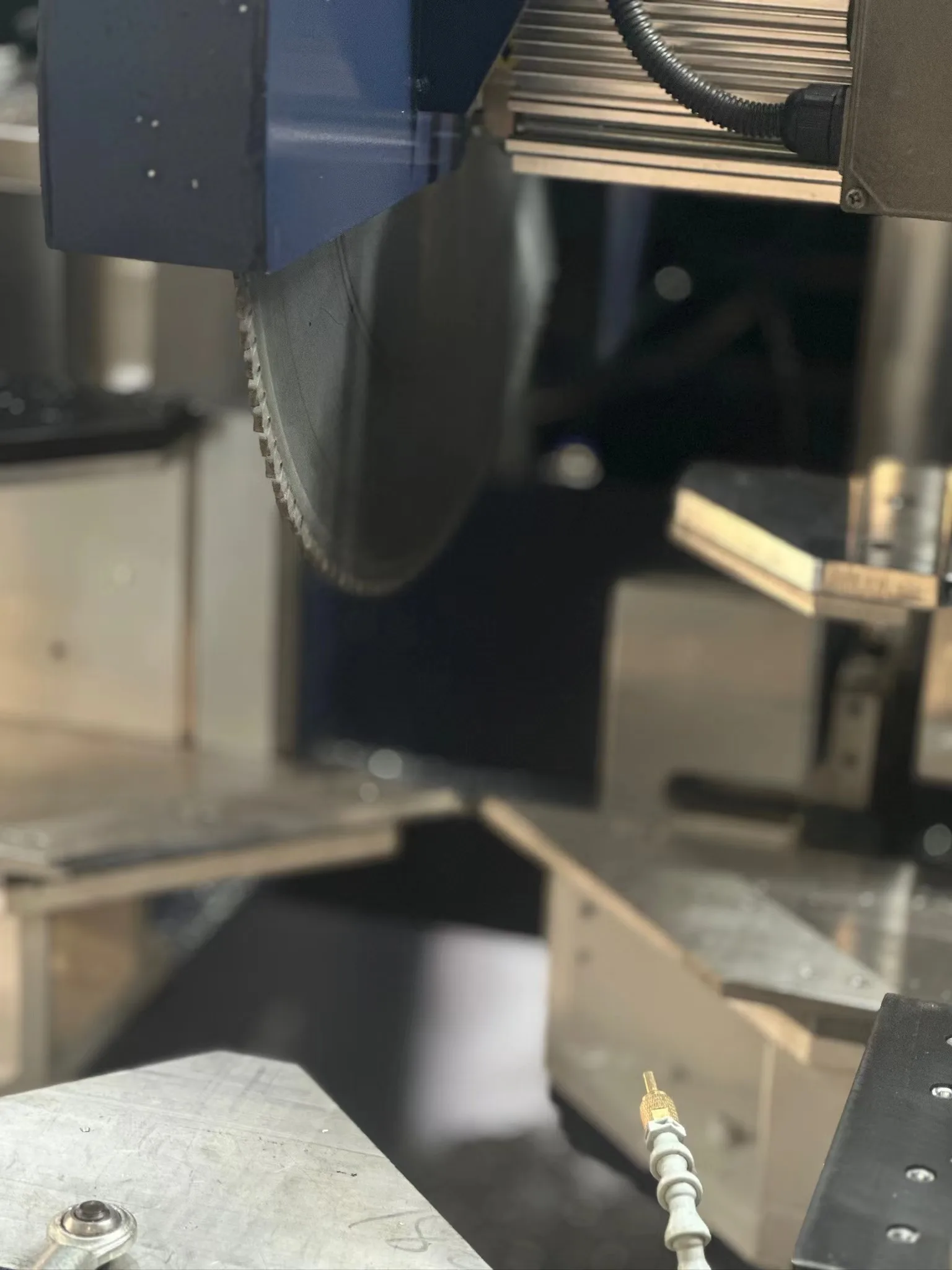

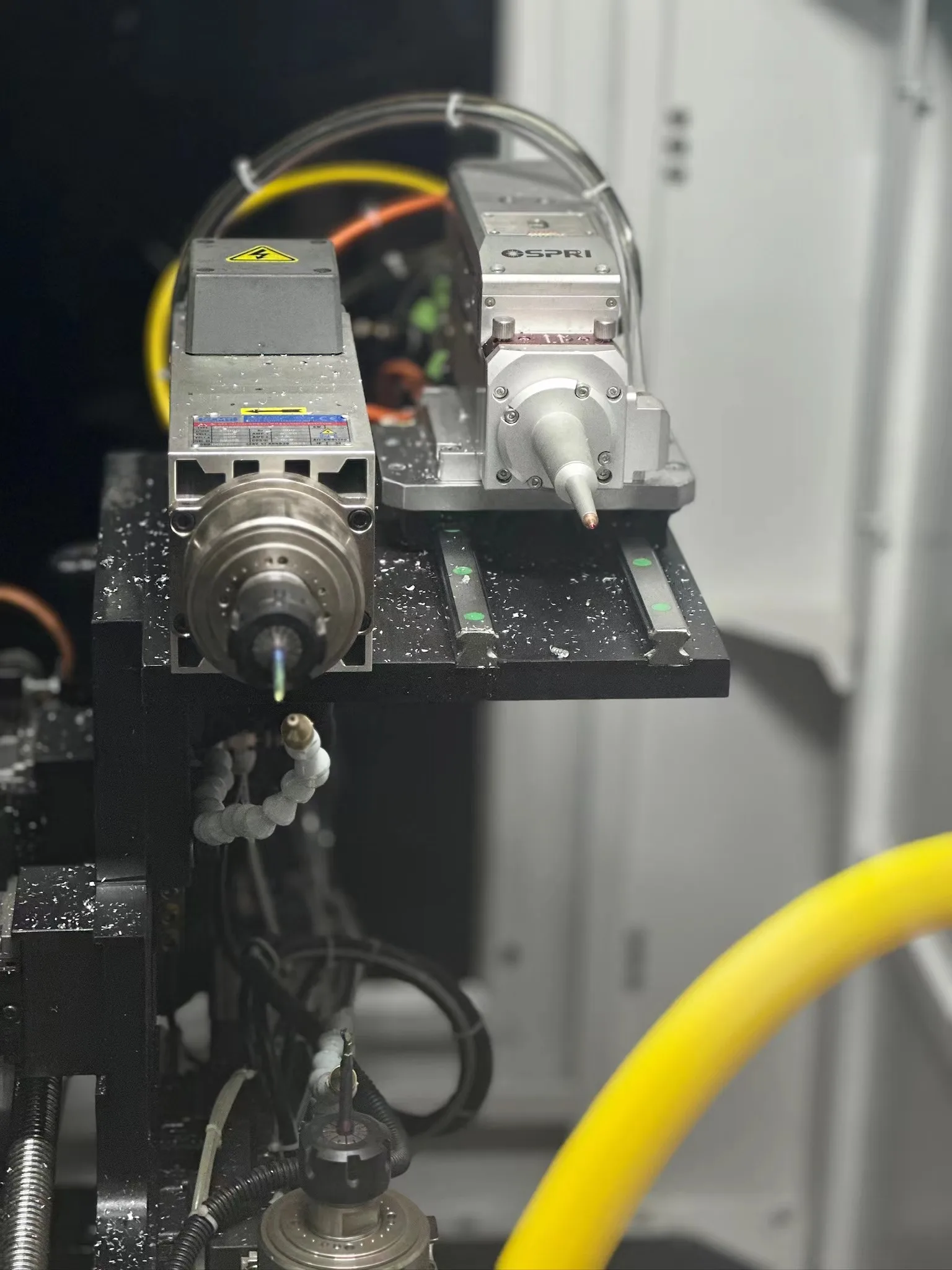

4.The drilling and milling part is equipped with double spindles and double lasers, which can drill and mill four sides and laser drill and draw lines on three sides (front, back and top).

5.Imported motor directly connected saw blade has smooth cutting and high machining accuracy. The new generation control system ensures the stable and reliable operation of the equipment.

6.The profle can be continuously cut at ±45* or 90°, and the processing efficiency is higher.

7.The enclosure is fully enclosed to ensure the safety of operators. 8.Bar code printer can be selected to set up E-Work digital factory system.

Specification

Our factory

Our Customer

Since the establishment of the factory, YBKE machines have been exported to more than 50 countries, and the glass equipment is famous for its reliability and durability. You can trust that your investment will be backed by a proven track record of success. Our R&D team is at the forefront of glass production technology. This means you will be able toAccess to the latest innovations to maintain a competitive advantage.

Packing & Delivery

1. Products can be packaged according to customer needs

2. Small machinery wooden box packaging.

3. For large machinery, first wrap a layer of film around the fuselage, then put it into a container, and use steel wires to fix the machine to ensure transportation safety and stability.

Our Service

Best-in-class after-sales support:

1. Our commitment to your success does not end with your purchase. We mention

Provide high-quality after-sales service to ensure that your equipment operates at its best without interruption.

2. Provide instructions and provide machine usage and installation videos (videos are provided in the customer's national language).

3. Provide video online guidance services and technical service groups. Customers can ask our technical service personnel if they have any questions during use.

Our Certificate

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd