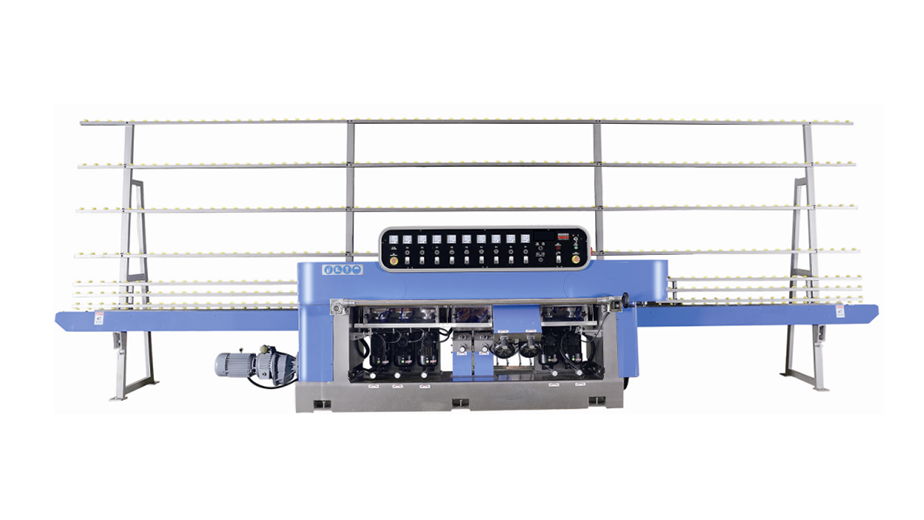

Automatic 3+1 End Milling Machine for Aluminium Windows & Doors

Time:2025-01-09 Browse:56次

Product Description

Performance feature:

☆ Suitable for sawing and milling of mortise and step surfaces of aluminum door and window sill profiles.

☆ Install a direct-connected motor, which can be rotated, milled and cut.

☆ A milling motor is controlled by three-axis CNC servo, without manual adjustment, it can quickly and conveniently complete the processing by selecting a preset program, and can continuously process profiles of different cross-sections.

☆ Using precision rack and pinion feed, more stable.

Company Introduction

Jinan YBKE Machinery Co.,Ltd is a professional manufacturer in the field of insulating glass and window-door processing equipment since 2008 in China. We focus on research and development, production and sales, broke through one after another technical problem on the way to success. We manufacture to control each machine quality from raw material to final machine. As a result, it has been well received by more than 50 countries from Europe, North America, Latin America, Middle East and Asian and has always maintained a good cooperative relationship. Every machine could be customized to meet your special requirement. We are committed to becoming the best supplier in China, whether it is service or product.

PRE-SALES:

Free consultation; Patiently answer customer questions; Give reasonable suggestions according to customer conditions.

AFTER-SALES:

* Track production progress, deliver on time, strictly inspect before leaving the factory to ensure product quality;

* Charter and book space, arrange delivery smoothly, prepare customs clearance documents, and assist customers in import customs clearance;

* Prepare equipment installation manuals and videos, after the equipment arrives, build the wechat group to help customers install and operate online.

* If customers need on-site service, we have professional engineers who can go to the customer's site to guide installation operations and staff training.

Free consultation; Patiently answer customer questions; Give reasonable suggestions according to customer conditions.

AFTER-SALES:

* Track production progress, deliver on time, strictly inspect before leaving the factory to ensure product quality;

* Charter and book space, arrange delivery smoothly, prepare customs clearance documents, and assist customers in import customs clearance;

* Prepare equipment installation manuals and videos, after the equipment arrives, build the wechat group to help customers install and operate online.

* If customers need on-site service, we have professional engineers who can go to the customer's site to guide installation operations and staff training.

Customer Visiting

Packing&Shipping

If you buy a few machines or big machine that need to be loaded in one or two containers, we pack this machine with several layers of stretch films and one layer of plastic film. If the order is not enough to be loaded in a container, we packed it in plywood case and send it to QINGDAO port to ship.

For the delivery time, it usually can be delivered in 5 working days.

For the delivery time, it usually can be delivered in 5 working days.

Exhibition

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd