YBKE Refined Machinery, Creating a New Tool for Door and Window Manufacturing

Time:2025-01-11 Browse:46次

Behind the booming development of the insulating glass door and window industry, it is inseparable from the strong support of advanced manufacturing machinery. As a company that has been deeply involved in the industry for many years, [name of the company manufacturing insulating glass door and window machinery] has made several major breakthroughs recently, injecting new vitality into the door and window manufacturing field.

After unremitting efforts by the company's R&D team, a new generation of intelligent CNC insulating glass production line was officially put into production. This production line integrates cutting-edge technologies such as artificial intelligence and big data, achieving unprecedented automation and intelligence. In the glass cutting process, the high-precision laser cutting head is equipped with an intelligent visual recognition system, which can quickly and accurately complete the cutting task according to the preset size, and the cutting accuracy error is controlled within an amazing [X] mm, which greatly reduces material waste and improves production efficiency by more than [X]%.

Not only that, the sealing and gluing process of the production line adopts a self-developed constant pressure intelligent gluing system to ensure that the sealant is evenly and stably applied to the edge of the glass to form a perfect sealing layer, effectively improving the airtightness of the insulating glass, far exceeding the industry standard. At the same time, the system can also monitor parameters such as glue quantity and pressure in real time. Once an abnormality occurs, it will automatically alarm and adjust immediately to ensure the continuity and stability of the production process.

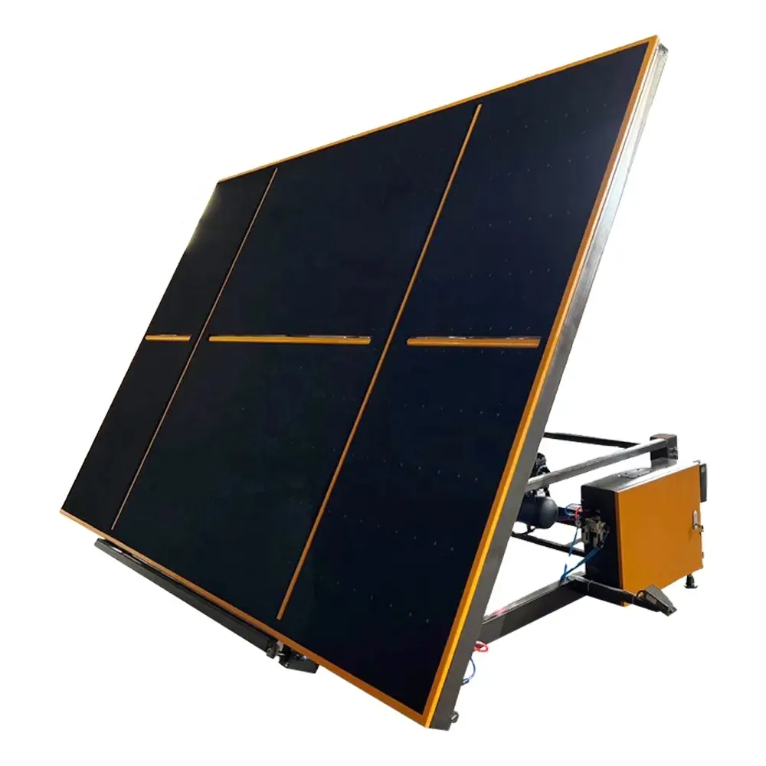

In order to meet the market demand for diversified door and window products, the company has also innovatively launched a multifunctional profile processing center. This equipment integrates multiple processes such as milling, drilling, and cutting. Through rapid tool switching and intelligent programming, it can easily process various complex shapes of door and window profiles. Whether it is a European classical style carved profile or a modern minimalist style special-shaped line, it can be perfectly presented, providing a broader design and creative space for door and window manufacturing companies.

In terms of quality control, [Name of the company manufacturing hollow glass door and window machinery] always adheres to strict standards. Each equipment must go through [X] strict testing procedures before leaving the factory, simulating various actual production environments, and repeatedly testing the performance, stability and durability of the equipment to ensure that the products delivered to customers are all fine products.

In addition to excellent products, the company has also won praise from customers with its comprehensive after-sales service. A professional team of after-sales engineers is on call 24 hours a day to provide customers with one-stop services such as equipment installation and commissioning, operation training, and fault repair. Once a customer encounters a problem, no matter where they are, technicians can solve the problem immediately through remote diagnosis or rush to the site to ensure that the customer's production is not affected.

With continuous innovation and research and development and persistent pursuit of quality, [Company Name of Manufacturing Hollow Glass Door and Window Machinery] is helping more and more door and window manufacturing companies to improve their competitiveness, break through the market wave, and work together to create a bright future for the hollow glass door and window industry.

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd