Revolutionizing UPVC Window Production with Advanced Machinery

Time:2025-07-01 Browse:14次

Revolutionizing UPVC Window Production with Advanced Machinery

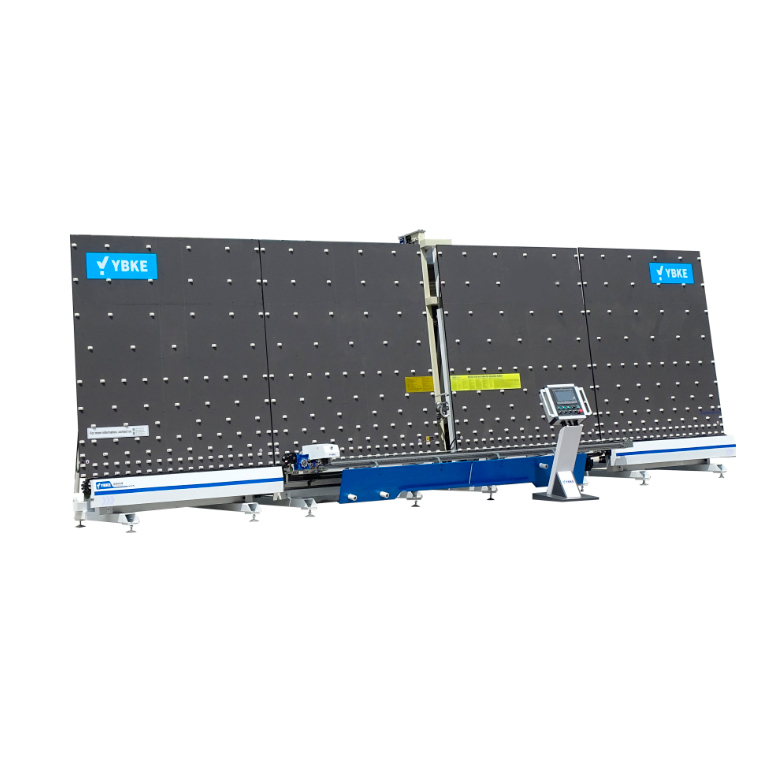

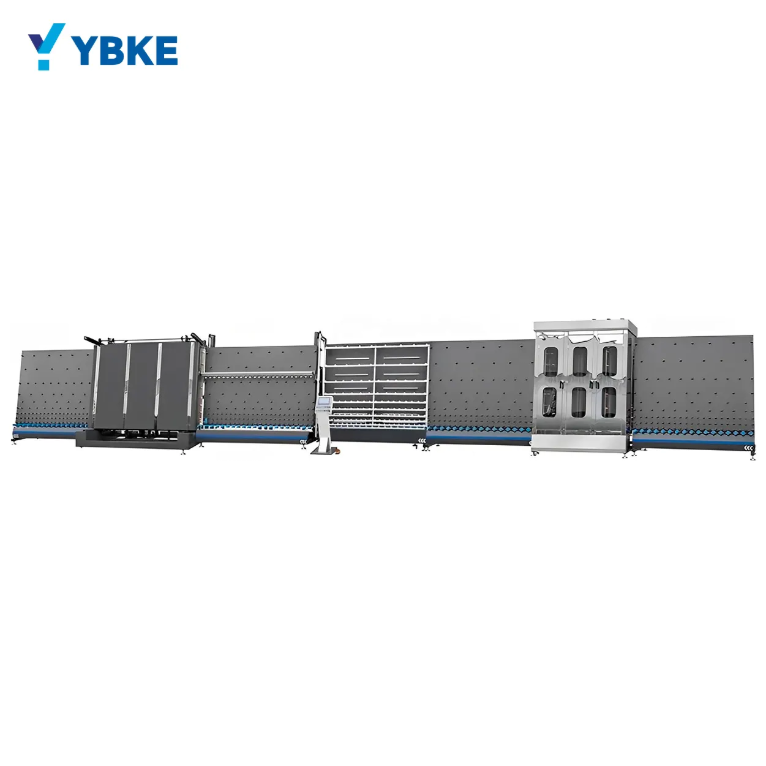

The global demand for energy-efficient buildings has propelled UPVC window machines to the forefront of modern construction. Jinan Inbeck Machinery’s UPVC processing systems combine precision extrusion, welding, and cutting to create durable, airtight windows that meet EU energy standards (e.g., EN 12608).

Technical Innovations:

· 5-Axis CNC Welding Center: Patented technology ensures 45° corner joints with ±0.1mm precision, eliminating air leaks. The machine’s dual-head design processes two windows simultaneously, increasing output by 60%.

· Automatic Profile Cutting System: Diamond-tipped blades cut UPVC profiles at 120m/min, with built-in barcode scanning with material tracking for zero waste.

· Integrated Sealing Unit: Robotic arms apply weatherstripping and thermal seals in a single pass, reducing labor costs by 40%.

Case Study: A German window manufacturer using our UPVC machine achieved a U-value of 1.3 W/m²K, surpassing local energy codes. "The machine’s ability to handle complex multi-chamber profiles without manual adjustments was key to our success," said their production manager.

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd

管理员

该内容暂无评论