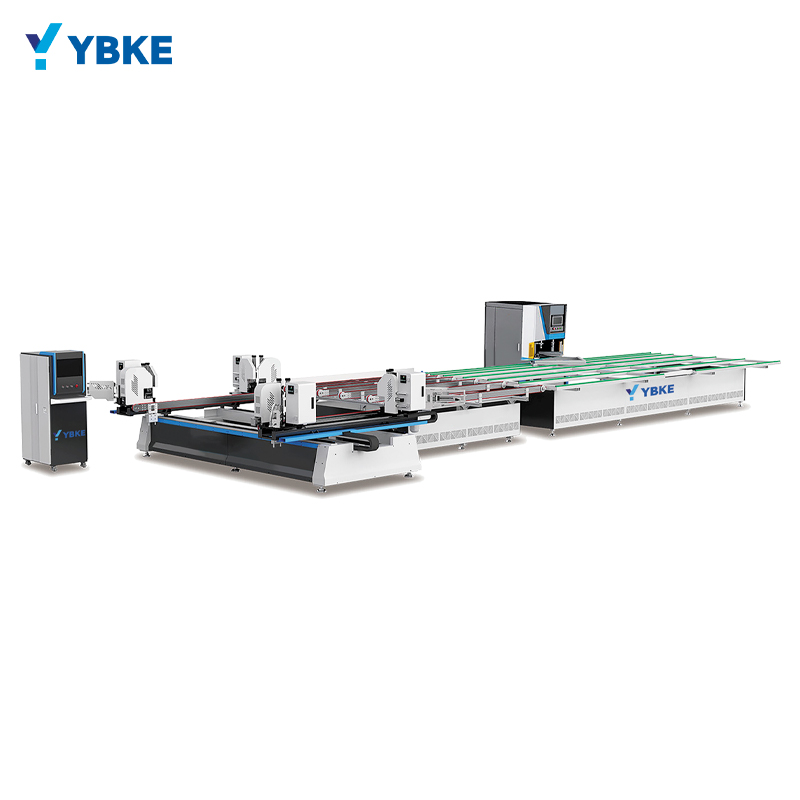

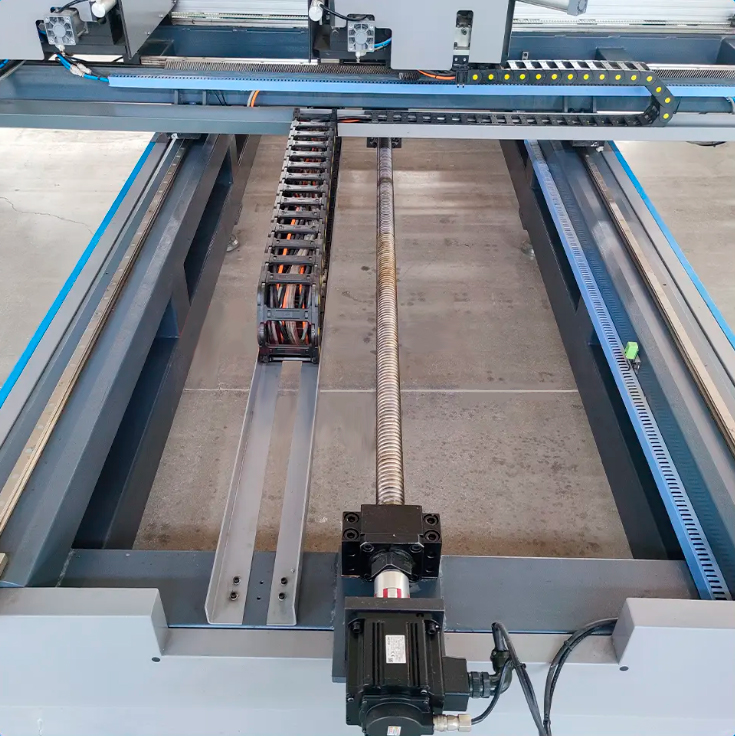

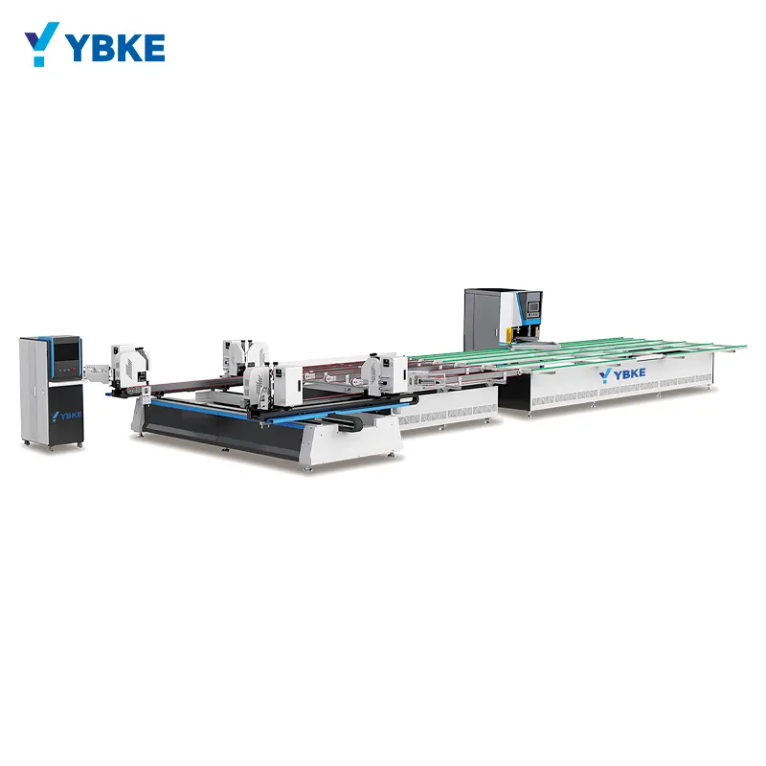

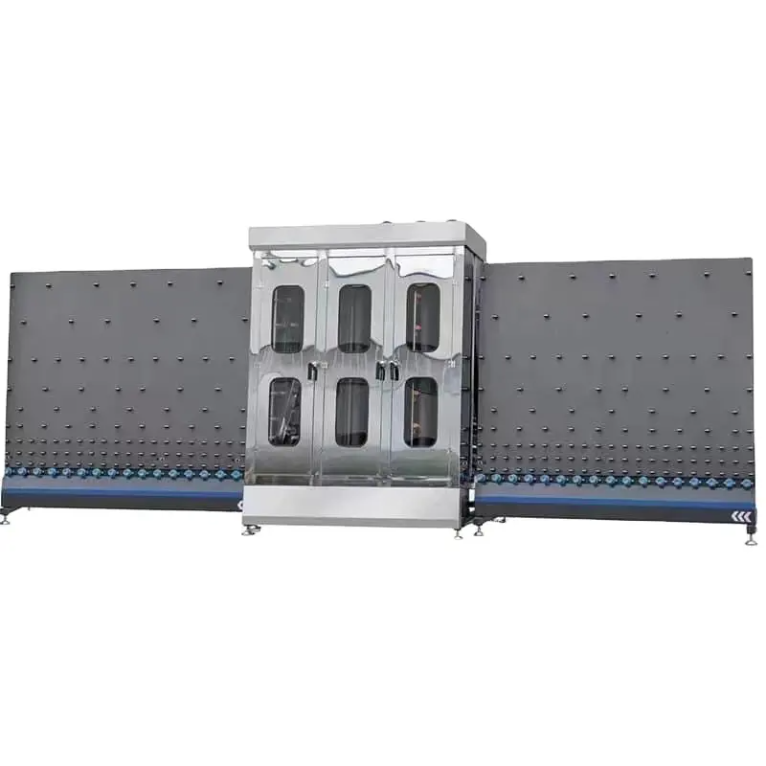

✅ The production line is specialized in welding and cleaning the outer corners of colored PVC profiles . It can weld and form a rectangular window frame at one time, clean the upper and lower welds, and then transfer the finished window to the corner cleaning unit through the transfer workbench to complete the cleaning of the outer corner welds of the finished window.✅ The whole machine extruder adopts high-precision tools made of Cr12MoV alloy, which are precision-processed after quenching. The tools are standardized and support tool interchange.✅The moving parts of this machine are all made of high-precision linear square guide rails, which ensures the stability and reliability of the equipment.✅ Equipped with color touch screen and Siemens PLC , driving large inertia servo motor, automatically completing the welding, transmission and cleaning of the outer corner welds of the window, easy to operate, stable and reliable performance.✅The frame is welded with thick-walled rectangular steel pipes, which has strong load-bearing capacity and is not easy to deform. The bed can be disassembled for easy transportation.✅Equipped with automatic blowing device, the weld after shearing can be blown off automatically.✅The corner cleaning unit adopts domestic well-known brand servo CNC system.✅The saw blade milling cutter adopts the spindle motor and is equipped with five sets of cutters as standard, which can realize the rapid cleaning of the upper and lower planes, facades, upper and lower rubber strip grooves and other parts of the window.✅ Equipped with USB port, which can realize the quick copying of multiple programs, and equipped with handheld remote control, which can realize manual teaching programming and automatic.✅ It can realize arc interpolation and linear interpolation, and can store processing programs for thousands of profiles. It is an essential equipment for large-scale door and wind companies to clean corner seams of multiple varieties and large quantities.✅The tools are driven by CNC axes, and the upper and lower broaches work simultaneously to ensure the beauty of weld cleaning.✅ Professional industrial appearance design achieves the perfect combination of practicality and beautiful appearance, bringing customers a high-end visual experience.

+86 18005412752

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd