Choosing the Right Aluminum Saw

Time:2025-09-10 Browse:14次

Choosing the Right Aluminum Saw: A Guide for Manufacturers

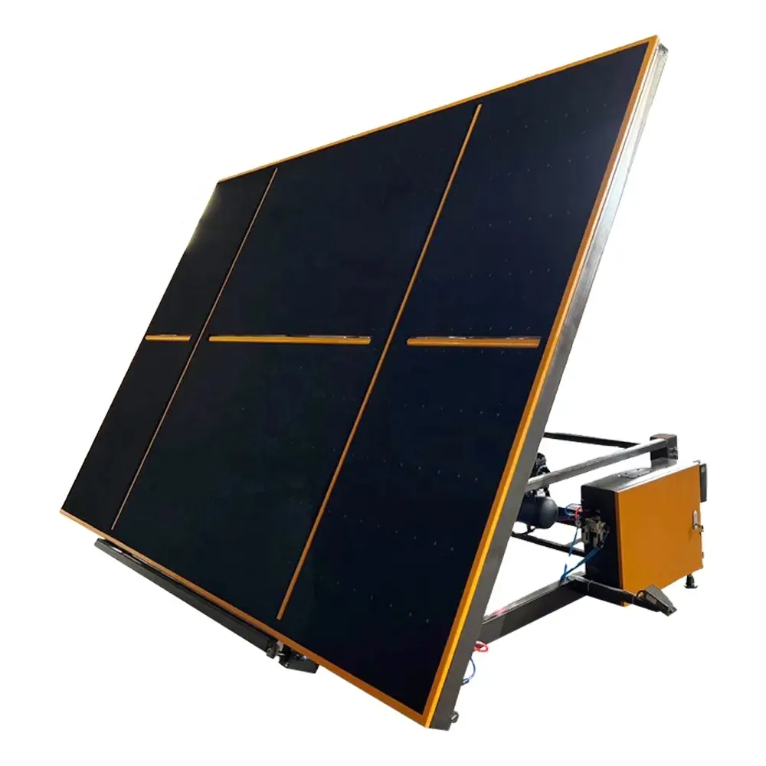

Not all aluminum saws are created equal—and selecting the right one depends on your production needs, material types, and output goals. As a leading provider of aluminum cutting machines, we’ve outlined key considerations to help you decide:

· For High-Volume Straight Cuts: Opt for a double head saw. Its dual blades process two profiles at once, ideal for large residential projects requiring hundreds of identical frames.

· For Angled Joints: A aluminum miter saw is essential. Look for models with digital angle readouts (±0.05°) to ensure tight 45° corners in windows and doors.

· For Mixed Production: A CNC aluminum cutting saw offers versatility. It switches between straight and angled cuts in seconds, perfect for manufacturers handling both standard and custom orders.

Pro Tip: Prioritize saws with automatic lubrication systems—they extend blade life by 300% and reduce maintenance downtime. Also, check for dust extraction features to keep workspaces clean and compliant with health standards.

“Investing in the right aluminum saw transformed our workflow,” said a Polish window manufacturer. “We went from 200 units/day to 450, with better quality across the board.”

Whatever your needs, our range of aluminum cutting machines—from basic saws to advanced CNC systems—has a solution designed to grow with your business.

Call to Action:

Ready to upgrade your production line? Request a personalized demo of our window and door making machinery, including PVC welding systems, aluminum cutting saws, and CNC solutions. Our technical team will help you select equipment that aligns with your goals.

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd

管理员

该内容暂无评论