Precision in PVC Welding

Time:2025-09-05 Browse:11次

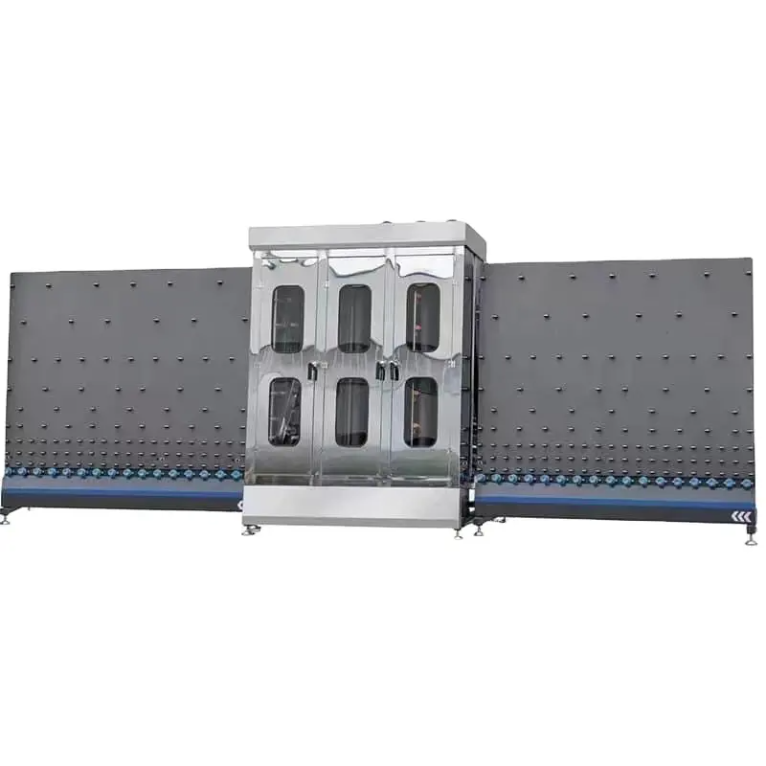

Precision in PVC Welding: How Advanced PVC Welding Machines Elevate Window Quality

For PVC window manufacturers, the strength and integrity of welded joints directly impact product performance. Our PVC welding machine redefines precision in this critical step, leveraging advanced technology to create seamless, long-lasting bonds that meet global standards (e.g., EN 12608).

Key features of our PVC welding machine include:

· Multi-axis Welding Heads: Simultaneously welds 45° and 90° corners with ±0.1mm alignment, eliminating air leaks that compromise insulation.

· Variable Temperature Control: Adjusts heat (200-260°C) based on PVC profile thickness, ensuring optimal fusion without material degradation.

· Automatic Deburring: Integrated tools remove excess plastic post-welding, reducing manual finishing by 70%.

A recent project for a 500-unit housing development in Southeast Asia showcased these capabilities. Using our machine, the manufacturer produced 3,000 PVC windows with consistent weld quality, passing rigorous water-tightness tests (1000Pa pressure) with zero failures. “The welding machine’s reliability cut our rework rate from 12% to 2%,” said their quality control lead.

Paired with our PVC window machine for profile cutting and assembly, it forms a complete solution that turns raw PVC into high-performance windows—efficiently and flawlessly.

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd

管理员

该内容暂无评论