CNC Four head vertical aluminum corner crimping machine for corner punching combination of aluminum window door

Time:2025-01-09 Browse:59次

Machine display

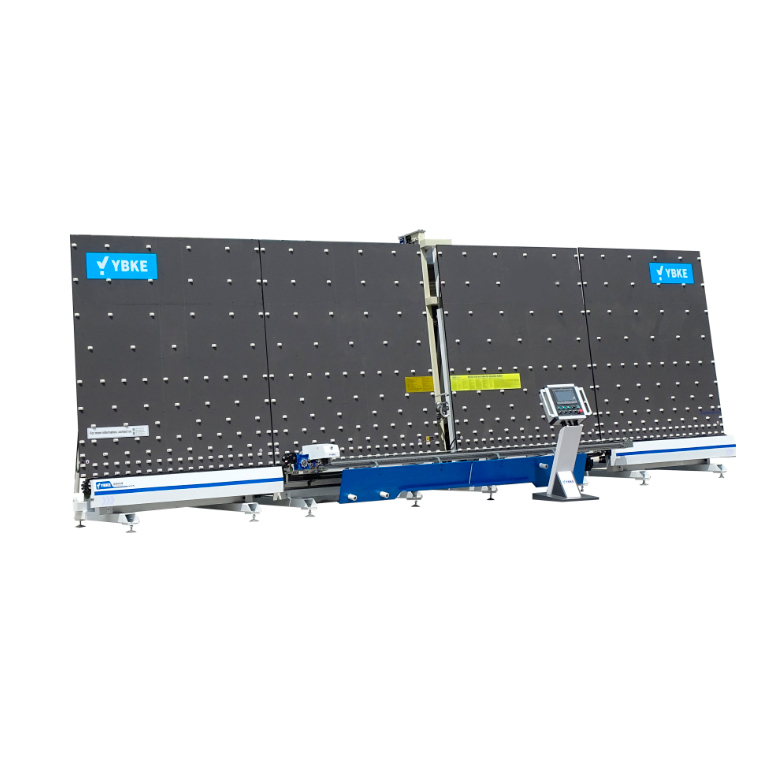

CNC Four Head Vertical Aluminum Corner Crimping Machine for Corner Punching Combination of Aluminum Window Door

YBLM4S-CNC-1800X3000

Used for the frame and corner forming process of aluminum doors and windows, and can complete the corner-code stamping connection of four corners at one time,,greatly improving the automation degree, saving time, labor and labor.Specification

★The Torque monitor function of the service system can auto-press the four corners, ensuring the processing accuracy.

★Air clamper can realize auto out and back horizontally. Easy to adjust shift motion, large motion range, lt can meet pressing requirements of all kinds of window and door type. To ensure the flatness before corner crimping.★Using upper fastening mode after adjusted corner cutter. Lock convenient and reliable.★Through pin hole connection to fasten oil cylinder and worktable.No need to adjust cutter. The cutter can be customized according to profile.★It equipped a retractable and auxiliary positioning device on each machine head,Convenient and reliable to work.

★It is more convenient to load and unload profile due to adopt lone motion of inner positioning oil cylinder.

Our factory

Our Customer

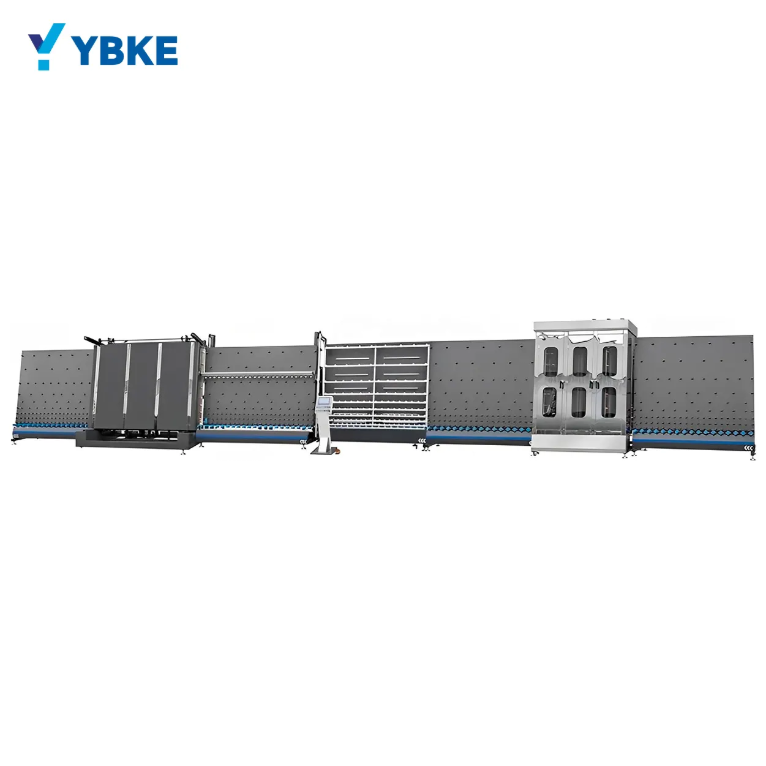

Since the establishment of the factory, YBKE machines have been exported to more than 50 countries, and the glass equipment is famous for its reliability and durability. You can trust that your investment will be backed by a proven track record of success. Our R&D team is at the forefront of glass production technology. This means you will be able toAccess to the latest innovations to maintain a competitive advantage.

Packing & Delivery

1. Products can be packaged according to customer needs

2. Small machinery wooden box packaging.

3. For large machinery, first wrap a layer of film around the fuselage, then put it into a container, and use steel wires to fix the machine to ensure transportation safety and stability.

Our Service

Customers are very satisfied with our engineers.

After the machine has been used for one or two years, it can be used for online service at any time

Best-in-class after-sales support:

1. Our commitment to your success does not end with your purchase. We mention

Provide high-quality after-sales service to ensure that your equipment operates at its best without interruption.

2. Provide instructions and provide machine usage and installation videos (videos are provided in the customer's national language).

3. Provide video online guidance services and technical service groups. Customers can ask our technical service personnel if they have any questions during use.

Our Certificate

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd