120mm Aluminum Profile Corner Crimping Machine For Aluminum Windows Marking

Time:2025-01-09 Browse:37次

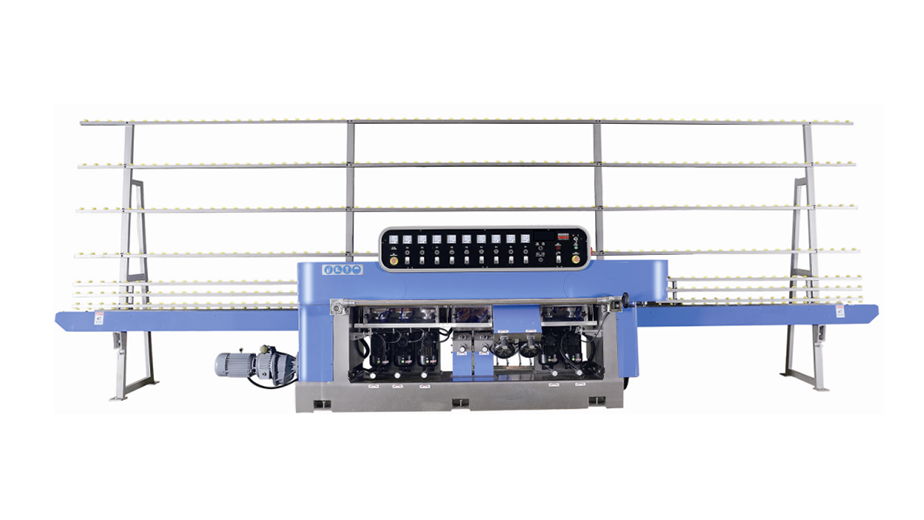

Machine display

1. Tool magazine design:Three sets of profile processing tools are installed to reduce tool changing time and increase work efficiency. Commonly used tools can be used fixedly for a long time.

Tool changing method: The tool holder rotates to change tools and locks, and the tool changing speed is 3 seconds.

2. The adjustment method is handwheel adjustment. The hand wheel cooperates with the counter to make the adjustment precise and remember the values when processing various profiles. When replacing the profile, adjust to the required value. The position adjustment is completed.

3. Positioning is pneumatic lift plus electric adjustment: pneumatic lift increases the convenience of placing and retrieving profiles during work; electric adjustment eliminates the need to disassemble the positioning plate when replacing profiles. The positioning plate can be electrically adjusted up and down.

4. Optimize the operation schedule to make the operation more comfortable for the staff.

5. The circuit design is optimized to minimize the cylinder stroke when wasting no work. The processing time of corner assembly is one-third faster than that of the same model. Save labor, time and electricity.

6. The mechanical transmission structure is an optical shaft matched with a copper sleeve. Under long-term and high-load working conditions, the wear is minimal and the service life is longest.

7. Simplify the positioning structure behind the profile, making adjustment more convenient and faster.

8. Assemble high-quality hydraulic station. The oil temperature heat dissipation function is added to ensure the service life of the working components and the power stability during long-term and high-load work.

Specification

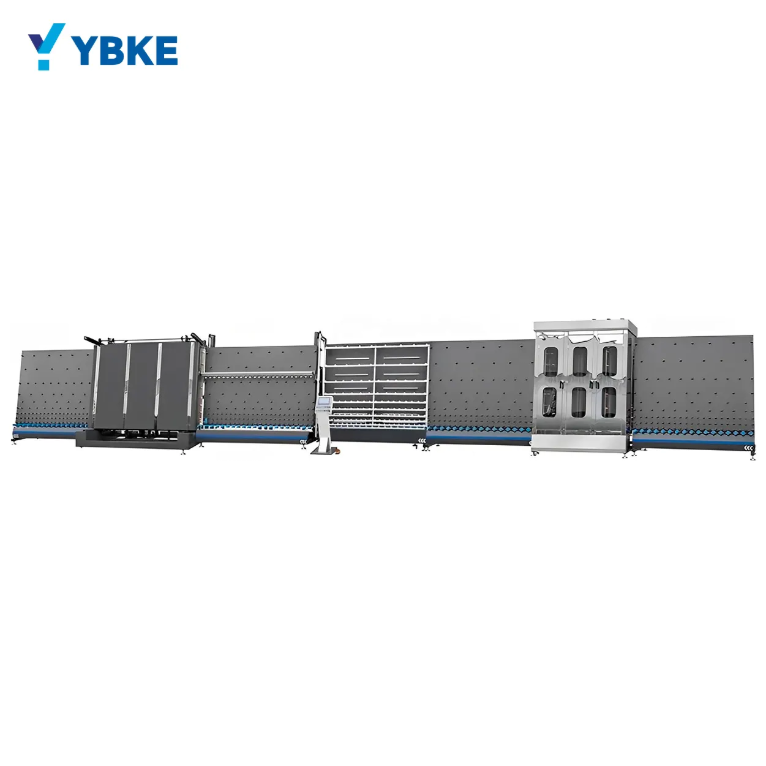

Our factory

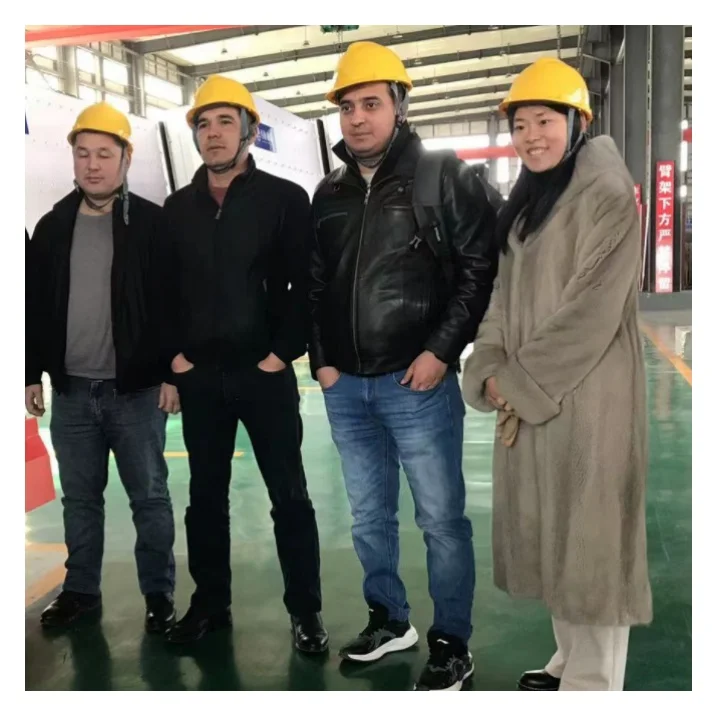

Our Customer

Since the establishment of the factory, YBKE machines have been exported to more than 50 countries, and the glass equipment is famous for its reliability and durability. You can trust that your investment will be backed by a proven track record of success. Our R&D team is at the forefront of glass production technology. This means you will be able toAccess to the latest innovations to maintain a competitive advantage.

Packing & Delivery

1. Products can be packaged according to customer needs

2. Small machinery wooden box packaging.

3. For large machinery, first wrap a layer of film around the fuselage, then put it into a container, and use steel wires to fix the machine to ensure transportation safety and stability.

Our Service

Best-in-class after-sales support:

1. Our commitment to your success does not end with your purchase. We mention

Provide high-quality after-sales service to ensure that your equipment operates at its best without interruption.

2. Provide instructions and provide machine usage and installation videos (videos are provided in the customer's national language).

3. Provide video online guidance services and technical service groups. Customers can ask our technical service personnel if they have any questions during use.

Our Certificate

Jinan YBKE Machinery Co., Ltd

Jinan YBKE Machinery Co., Ltd